News

Contact Us

Phone : +86 0531-85908792

Email:Admin:zrsuns@outlook.com Sales:sales@rubylasercutting.com

Skype: ZRsunslaser

Q Q: 2407603284

Mobile :+86-13295411923

Industry News

How to better utilize the production efficiency of CO2 laser engraving machines

- source:Jinan Ruby Laser Technology Co., Ltd

- author:

- time:2023-06-08 19:39:55

How to better utilize the production efficiency of CO2 laser engraving machines

1. Good grounding

The CO2 laser power supplies and CO2 laser engraving machine tool bed must have good grounding protection, and the grounding wire should be less than 4 ω Dedicated ground wire for. The necessity lies in: (1) ensuring the normal operation of the laser power supply, (2) extending the service life of the laser tube, (3) preventing external interference from causing machine tool jumping, and (4) preventing accidental circuit damage caused by high-voltage discharge. Good grounding is essential!. For good quality laser power source, please visit below website. www.rlaserpowersupply.com

2. Cooling water should be unobstructed

Whether using tap water or circulating water pumps, it is necessary to maintain smooth water flow. Cooling water takes away the heat generated by the laser tube, and the higher the water temperature, the lower the light output power (preferably at 15-20 ℃ water temperature); When water is cut off, the tube end may explode due to heat accumulation in the laser cavity, and even damage the laser power supply. So it is necessary to check whether the cooling water is smooth at any time. When the water pipe has a hard bend (dead bend) or falls off, leading to the failure of the water pump, it must be repaired in a timely manner to avoid power reduction or even equipment damage.

3. Cleaning and maintenance, good ventilation, and wiping at any time

The cleaning and maintenance of CO2 cutting machine tools is a necessary condition for their normal operation. Imagine if a person's joints are not flexible, how can they move? Similarly, the laser engraver guide rail is a high-precision core component that must be wiped clean and lubricated after each task is completed; Each bearing also needs to be regularly oiled in order to make the drive flexible, the 2D code CO2 engraving process precise, and extend the service life of the laser engraving machine.

4. Environmental temperature and humidity

The ambient temperature should be within the range of 5-35 ℃. Special attention should be paid to: if used in environments below freezing point, it is necessary to: (1) prevent the circulating water inside the glass CO2 laser tube from freezing, and thoroughly discharge the water after shutdown; (2) When starting up, the laser current must be preheated for at least 5 minutes before it can work. In rainy and humid days and environments, the laser power supply needs to be preheated for a longer time. Only after removing moisture can high voltage be applied to prevent breakdown of the high voltage circuit.

5. Correct use of the "Laser High Voltage" key

When the "Laser High Voltage" button is turned on, the CO2 power supply is in a standby state. If it encounters "manual laser output" or computer misoperation, it will emit laser light, unintentionally injuring people or objects. Therefore, it is required to turn off the "laser high voltage" at any time when completing a task, such as discontinuous processing (laser current can not be turned off), and the operator is prohibited from leaving without authorization during machine operation to avoid accidents. It is recommended to work continuously for less than 5 hours and rest for 30 minutes in between.

6. Stay away from high power and strong vibration equipment

Sudden interference from high power can sometimes cause machine malfunction, although it is rare, it should be avoided as much as possible. Therefore, large electric welding machines, giant power mixers, and large power transmission and transformation equipment should be kept away. It goes without saying that strong vibration equipment, such as forging presses, vibrations caused by close range motor vehicles, etc. The obvious shaking on the ground is very detrimental to accurate QR code engraving.

7. Lightning protection

As long as the lightning protection measures for buildings are reliable. The first article, "Good grounding", can also help prevent lightning.

Special suggestion: In areas with unstable grid power (such as voltage fluctuations exceeding 5%), users should install a regulated power supply with a capacity of at least 3000W or above to prevent sudden voltage fluctuations from burning out the circuit or computer.

8. Maintain and control the stability of the PC.

The control PC is mainly used for controlling engraving equipment. Unless necessary graphic design software is installed, please do not use it exclusively for personal use.

Due to the installation of network cards and antivirus firewalls on the computer, it can seriously affect the speed of the control computer. Please do not install an antivirus firewall on the control machine. If you need a network card for data communication, please disable the network card before starting the laser engraving machine.

9. Maintenance of guide rails: During the movement of the guide rails, a large amount of dust will be generated due to the processed materials. Maintenance method: First, use a cotton cloth to wipe off the original lubricating oil and dust on the guide rail. After wiping it clean, apply a layer of lubricating oil on the surface and sides of the guide rail. Maintenance interval: About one week.

10. Maintenance of the fan: After a period of operation, a large amount of dust will accumulate in the fan and exhaust duct, which can affect the exhaust efficiency of the fan and cause a large amount of smoke and dust to be unable to be discharged. Maintenance method: Loosen the connecting clamp between the exhaust duct and the fan, remove the exhaust duct, and clean the dust from the exhaust duct and fan. Maintenance cycle: About one month.

11. Screw fastening: after the Motor system works for a certain time, the screw at the motion connection will become loose, which will affect the stability of mechanical movement. Maintenance method: Use the randomly provided tools to tighten the screws one by one. Maintenance cycle: About one month.

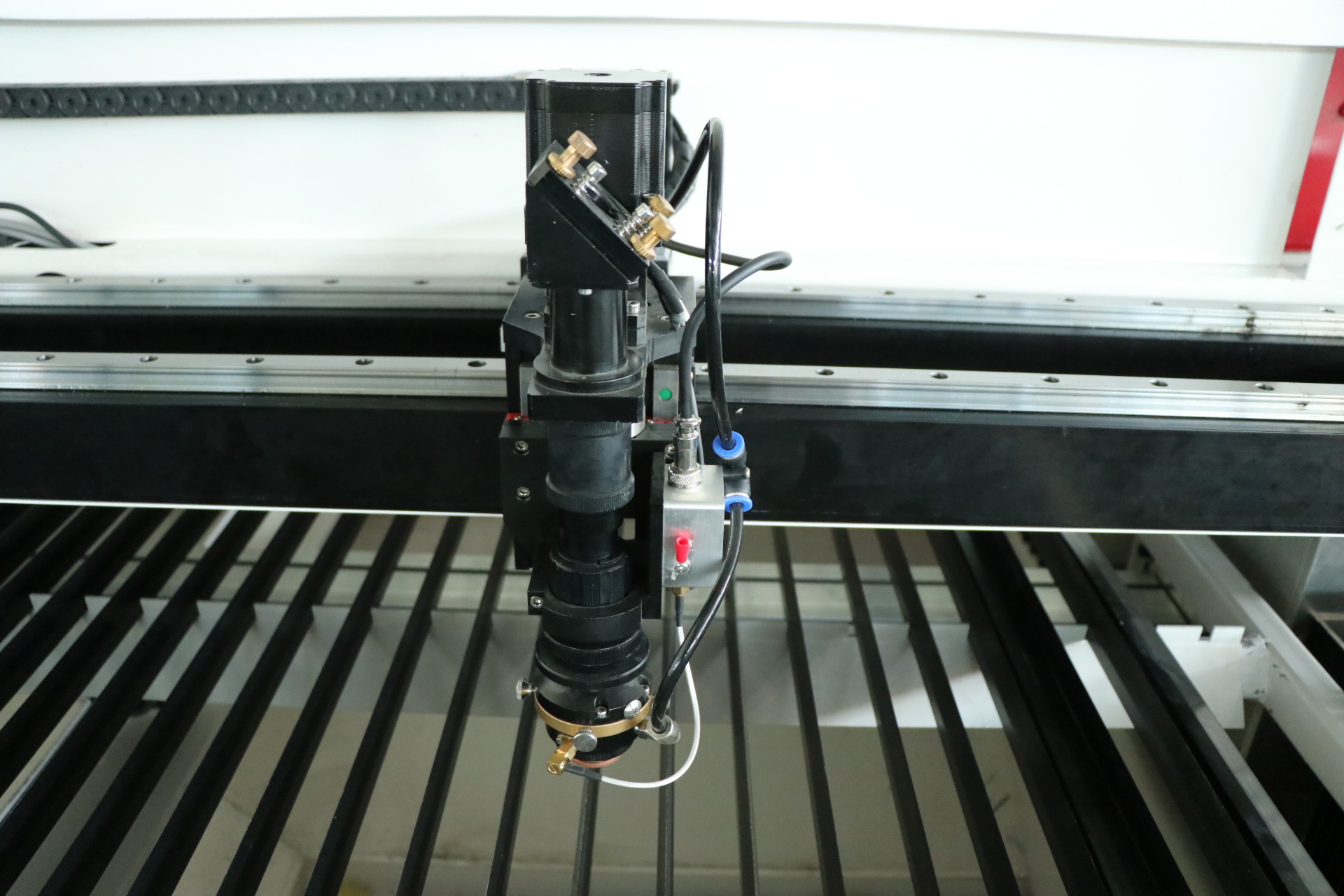

12. Focus lens maintenance: After the machine has been working for a period of time, a layer of gray will be adhered to the surface of the Znse focus lens due to the working environment, which will reduce the reflectivity of the reflecting lens and the transmittance of the CO2 focus lens, ultimately affecting the working power of the laser. Maintenance method: use Cotton wool dipped in ethanol to gently wipe the lens surface clockwise to remove dust.

- Previous:How to apply certifications for South Korea market

- Next:没有了

News

-

2023-07-13 17:08:52

How precautions...

-

2023-06-08 19:39:55

How to better u...

-

2023-05-15 10:40:31

How to apply ce...

-

2023-04-24 16:57:25

Leading laser p...

-

2023-04-11 16:06:33

Zhonggu Lianchu...

-

2021-01-03 01:08:29

What is the pra...

2407603284

2407603284  ZRsunslaser

ZRsunslaser